Are you in the market for a reliable and efficient water pump? Look no further than centrifugal water pumps. These powerful machines have a wide range of applications in industries such as agriculture, mining, and chemical processing. In this article, we'll cover everything you need to know about centrifugal water pumps, from their basic principles to how to choose the right manufacturer.

A centrifugal water pump is a machine that uses centrifugal force to move water through a system. It works by converting rotational energy from a motor or engine into kinetic energy, which is used to move water through the pump and out into the system. These pumps are typically used to move large volumes of water quickly and efficiently, making them ideal for a variety of applications.

Centrifugal water pumps are essential to a wide range of industries, including agriculture, manufacturing, construction, and many others. These pumps are used to move water for irrigation, cooling, and a variety of other purposes. Without centrifugal water pumps, many industries would not be able to operate efficiently or effectively.

Centrifugal force is the force that pushes an object away from the center of rotation. It is the force that causes water to move through a centrifugal water pump. The basic principle of centrifugal force is that when an object is rotating, any object attached to it will also rotate. As the object rotates, centrifugal force is generated, which pushes the water through the pump and out into the system.

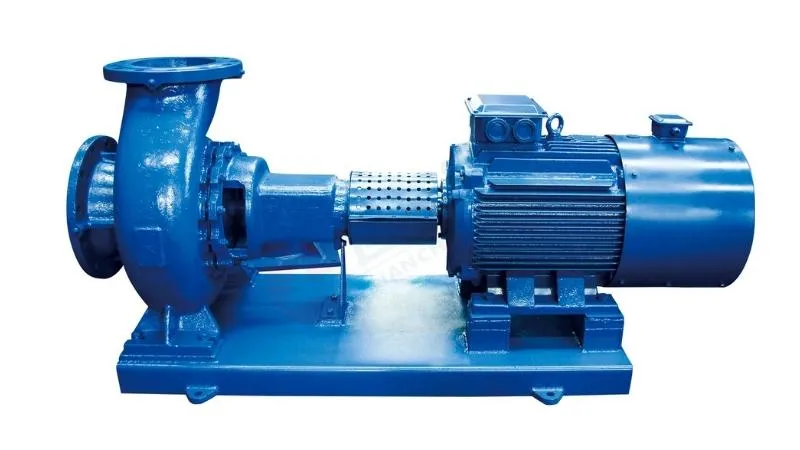

A centrifugal water pump consists of several different parts, including an impeller, a casing, a suction pipe, and a discharge pipe. The impeller is the rotating part of the pump that generates centrifugal force. The casing is the stationary part of the pump that contains the impeller and directs the flow of water. The suction pipe is the part of the pump that draws water into the pump, while the discharge pipe is the part of the pump that pushes water out of the pump and into the system.

The working principle of a centrifugal water pump is based on the transfer of rotational energy into kinetic energy. When the impeller rotates, it generates centrifugal force, which pushes water through the pump and out into the system. As the water is pushed through the pump, it gains kinetic energy and moves through the system at a high rate of speed.

Centrifugal water pumps are complex machines that consist of several components working together to achieve efficient pumping. The following are some of the main components of a centrifugal water pump:

Impeller: The impeller is the primary rotating component of the pump and is responsible for creating the centrifugal force necessary for the pump to move water. It consists of a series of curved vanes that push water outwards as it rotates.

Casing: The casing is the outer shell of the pump and provides support for the impeller and other components. It is designed to direct the flow of water into and out of the impeller.

Shaft: The shaft connects the impeller to the motor and transmits the rotational force from the motor to the impeller.

Motor: The motor provides the power needed to drive the impeller and pump water. It is usually an electric motor, but diesel or gasoline engines may also be used.

Bearings: Bearings support the rotating shaft and allow it to rotate smoothly.

Seal: The seal is used to prevent water from leaking along the shaft where it exits the pump. Different types of seals are used depending on the specific application.

Suction and discharge piping: The suction piping connects the pump to the water source, while the discharge piping connects the pump to the system that is being supplied with water.

Centrifugal water pumps are frequently used in various industries because they can move substantial amounts of fluids effectively. These industries include agricultural irrigation, industrial applications, fire suppression systems, domestic water supply, mining operations, oil and gas extraction, and chemical processing.

In agriculture, centrifugal water pumps are frequently employed to irrigate crops by moving water from a source like a river or lake to the fields. The ability of these pumps to handle significant amounts of water efficiently, coupled with their ease of use and maintenance, make them preferred in the agricultural sector.

Centrifugal water pumps are also widely used in industrial applications, including moving fluids around the facility, pumping chemicals, and removing wastewater. These pumps are essential for industrial processes that require fluid movement. They can handle different types of fluids, making them suitable for use in various industries.

The pumps are a crucial component of fire suppression systems because they can move water quickly from a source like a fire hydrant to the fire's location. The high flow rate of the pump makes it essential in any fire suppression system.

Centrifugal water pumps are frequently used in homes to supply water for washing, bathing, and cooking, among other purposes. They are often utilized with water storage tanks or wells to ensure a reliable water supply. The pumps' low maintenance requirements and capacity to handle a wide range of water pressures make them preferred in domestic water supply applications.

Centrifugal water pumps are widely used in mining operations to dewater mines, transport water from underground mines, and remove excess water. These pumps are preferred in mining operations because they can handle significant amounts of water and require relatively low maintenance.

The oil and gas industry employs centrifugal water pumps to transport water, drilling mud, and other fluids to the wellbore during drilling operations. These pumps are also used to transport oil and gas during production. They are preferred in the oil and gas industry due to their reliability, efficiency, and capacity to handle different fluids.

Centrifugal water pumps are frequently used in chemical processing plants to transport fluids between different stages of the manufacturing process. They can transport chemicals, solvents, and other fluids through pipelines and vessels. The pumps' easy operation, minimal maintenance requirements, and capacity to handle different chemicals and solvents make them preferred in chemical processing applications.

When it comes to selecting a suitable centrifugal water pump, the process can be quite overwhelming due to the multitude of models and manufacturers available. There are several essential factors to consider when making a decision:

This refers to the volume of water that can be moved by the pump over a specific period, typically measured in gallons per minute (GPM). It is imperative to choose a pump with a flow rate that corresponds to your unique requirements, whether it is for household use or industrial purposes.

This refers to the amount of pressure the pump can generate to move water vertically, usually measured in feet of head. It is crucial to select a pump that can produce enough head pressure to meet the demands of your specific application.

The power needed to operate the pump is usually measured in horsepower (HP). It is essential to select a pump with the appropriate amount of power to match the flow rate and head pressure required for your application.

The environment in which the pump will operate must be considered, including factors such as temperature, humidity, and altitude. It is necessary to ensure that the chosen pump can function safely and efficiently under the specific conditions of your application.

The materials used to construct the pump, including the impeller, casing, and motor, must be evaluated to guarantee they are durable and corrosion-resistant for extended usage.

The maintenance requirements of the pump, including routine inspections, cleaning, and replacement of parts, must be considered. It is crucial to choose a pump that is simple to maintain and has easily available replacement parts.

Centrifugal water pumps are renowned for their ability to provide a myriad of advantages over other types of pumps. These advantages have led to their widespread adoption in numerous applications. Among the most notable benefits of centrifugal water pumps are:

Centrifugal pumps are unparalleled in their efficiency, with many models capable of achieving efficiency levels of around 70-80%. This translates to a significant volume of water being transported while consuming relatively low amounts of energy.

Centrifugal pumps possess a straightforward design and require minimal maintenance when compared to other types of pumps. Regular upkeep and cleaning can ensure that the pump remains in optimal working order.

Centrifugal pumps can function seamlessly across a broad spectrum of conditions, from low flow rates to high head pressures. This versatility enables their use in a wide variety of applications, including but not limited to domestic water supply and chemical processing.

Centrifugal pumps have a relatively uncomplicated design that consists of a limited number of moving parts. This simplicity contributes to ease of installation and operation while simultaneously reducing the risk of mechanical failures.

_1683258092_WNo_800d450.webp)

While centrifugal water pumps offer many advantages, there are also some limitations to consider when selecting a pump for your application. Here are a few limitations to keep in mind:

Centrifugal pumps are not well-suited for applications that require suction lift, as their suction lift capacity is limited. This means that they may not be able to draw water from a source that is located below the pump.

Centrifugal pumps are sensitive to changes in operating conditions, such as changes in flow rate or head pressure. If these conditions change too much, the pump may not be able to operate effectively.

Centrifugal pumps are not ideal for applications that involve pumping large solids or viscous liquids, as these can cause damage to the impeller and reduce the pump's efficiency.

The efficacy and functionality of a centrifugal water pump can be swayed by an array of factors. Grasping these factors can aid in optimizing the pump's functionality and guaranteeing that it functions as optimally as feasible.

One salient factor to contemplate is the pump's efficacy. The efficiency of a centrifugal pump is the proportion of the power input to the power output. A more efficient pump will necessitate less power to attain the identical flow rate and head pressure as a less efficient pump. To compute the efficiency of a centrifugal pump, the ensuing equation can be utilized:

Efficiency (%) = (Output Power / Input Power) x 100

Another consequential factor to deliberate is maintenance. In order to uphold peak performance, it is paramount to maintain cleanliness and keep your pump well-maintained. This includes regularly inspecting the impeller, volute, and other components for indicators of deterioration or impairment, and replacing any damaged parts as necessary. Additionally, lubricating the pump and routinely scrutinizing the pump's bearings and seals are of the utmost importance.

Other factors that can sway the efficacy and functionality of a centrifugal water pump are the operational circumstances, such as the flow rate, head pressure, and power requirements. The materials utilized in the fabrication of the pump can also have an influence on its efficacy and functionality, as can the choice of impeller and other components.

Centrifugal water pumps are considered generally safe for use, but there exist certain potential dangers that require operators to be aware of. To ensure the safe operation of centrifugal pumps and prevent accidents, the following safety measures must be taken into account:

Given that centrifugal pumps are driven by electricity, there exists an electrical danger that should not be ignored. Before starting to work on the pump, it is crucial to turn off the power and disconnect the pump from its energy source. Moreover, it is essential to ensure that the wiring and electrical components are in proper condition and well-grounded.

Certain applications of centrifugal water pumps necessitate the pumping of hazardous chemicals. It is important to make sure that the pump is designed specifically for the chemical being pumped, and that the operator has received adequate training on how to handle hazardous materials. Furthermore, it is critical to wear appropriate personal protective equipment, such as gloves and goggles, when working with such chemicals.

The mobile parts of a centrifugal pump can pose a mechanical danger. Before conducting any maintenance or repairs on the pump, it is important to guarantee that the pump is properly isolated and secured. It is also crucial to never touch the impeller or any other mobile parts while the pump is operational.

The high rotational velocity of the impeller and other mobile parts can create a risk of injury to operators. To prevent injury, it is imperative to ensure that all guards and protective covers are in position and properly secured prior to operating the pump.

_1683258114_WNo_800d450.webp)

Centrifugal water pumps have gained a reputation as the most prevalent pump type, yet several other pump varieties find utility in various applications. One such kind that often attracts comparison to centrifugal pumps is the positive displacement pump.

The principal variance between centrifugal and positive displacement pumps is their operative principle. Centrifugal pumps employ centrifugal force to transport fluids, whereas positive displacement pumps rely on the mechanical motion of a revolving part to move fluids.

In a positive displacement pump, a rotating piece like a gear or piston brings about a vacuum that draws the fluid into the pump, then forces it out via the discharge. Because of this mechanical manipulation, positive displacement pumps are often more fitting for pumping fluids with elevated viscosity or solids content.

However, centrifugal pumps outmatch positive displacement pumps in efficiency and perform better when pumping fluids with lower viscosity and reduced solids content. Additionally, centrifugal pumps tend to be more economical and simpler to maintain than positive displacement pumps.

Jet pumps, often likened to centrifugal pumps, are a different kind of pump altogether. Such pumps utilize the force of suction and centrifugal force in unison to facilitate fluid movement.

To expound, high-pressure fluids such as water, create a vacuum which, in turn, sucks fluid from its source, thereby, propelling the liquid into the pump and through the impeller. The fluid is then accelerated, and ultimately ejected through the discharge outlet.

Although jet pumps are used in farming and residential settings, they are less efficient compared to their centrifugal pump counterparts. Furthermore, their lifting capacity is limited, thus, making them unsuitable for applications that require high suction or lift.

Maintaining the proper functioning and durability of a centrifugal water pump is of utmost importance. Routine maintenance procedures can prevent untimely breakdowns, decrease the likelihood of accidents, and save a considerable amount of money over time. However, the question of how often one should perform maintenance on a centrifugal water pump remains unanswered.

The frequency of maintenance hinges on various factors, including the age of the pump, the amount of use it receives, and the operating conditions. As a rule of thumb, it is advisable to have the pump inspected and serviced at least once annually, preferably before the start of its operating season.

The inspection process should entail an exhaustive check-up of the pump's components to identify and address any wear and tear, corrosion, or damage that may exist. The impeller, casing, and seals should be cleaned and lubricated when necessary. The motor should be examined to ensure proper alignment, belt tension, and electrical connections. The pump's performance should also be evaluated to verify that it is functioning at its intended capacity.

In addition to the yearly inspection, some day-to-day maintenance tasks that the pump operator can carry out include checking the oil level, monitoring the temperature and pressure gauges, and keeping an ear out for any abnormal sounds or vibrations.

If the centrifugal water pump is being used in severe or strenuous conditions, like pumping abrasive or corrosive liquids, it may necessitate more frequent maintenance. Likewise, if the pump is being used for critical applications, like fire protection, it should undergo more frequent inspections and tests.

It's important to understand that maintenance should only be performed by trained professionals who possess extensive experience handling centrifugal water pumps. Attempting to do maintenance without adequate knowledge or tools can be perilous and may cause damage to the pump or injury to the operator.

_1683258130_WNo_800d450.webp)

When selecting a manufacturer for a centrifugal pump, there are numerous considerations to weigh. Here are a few pointers to assist you in making the best decision:

Opt for a manufacturer with an established reputation in the industry. Examine their website and assess feedback from other clients to gain a sense of their reputation.

Verify that the manufacturer employs top-quality materials and adheres to rigorous quality control processes. This will guarantee that the pump you receive is of superior quality and has a lengthy lifespan.

Choose a manufacturer with extensive experience in the field. They will possess the knowledge and expertise necessary to provide you with the finest pump for your requirements.

Determine if the manufacturer can personalize the pump to your precise requirements. This will guarantee that the pump is tailored to your needs and performs optimally.

Select a manufacturer that provides excellent service and support. They should be able to help you with any queries or problems you may have and provide prompt solutions.

Compare costs from different manufacturers to ensure that you are receiving a reasonable price for the pump. However, do not compromise on quality or service for a lower price.

Examine the manufacturer's delivery time and ensure that it corresponds with your project schedule.

Determine if the manufacturer offers after-sales service, including maintenance and repair services. This will ensure that your pump continues to function optimally throughout its lifetime.

In conclusion, centrifugal water pumps are an essential piece of equipment in many industries. Their simple design, high efficiency, and low maintenance requirements make them a popular choice for a variety of applications. If you're in need of a centrifugal water pump, be sure to check out our website at www.liancheng-pump.com for a wide selection of quality pumps from a trusted manufacturer.

.png)