Basic overview of double suction water pump

Working principle of double suction water pump

Application field of double suction water pump

Features and advantages of double suction water pump

Classification of double suction water pumps

The difference between single suction pump and double suction water pump

How to choose a double suction water pump?

Care and Maintenance of double suction water pumps

Double suction water pump is a commonly used liquid conveying equipment, which is widely used in the fields of industry, construction, agriculture and water conservancy projects. Its unique design enables it to draw liquid from two suction ports simultaneously, providing greater flow handling capacity. Whether you are interested in double suction water pumps or want to learn more about liquid transfer, this article will provide you with valuable information and insights. Let's start exploring the mysteries of double suction water pumps together!

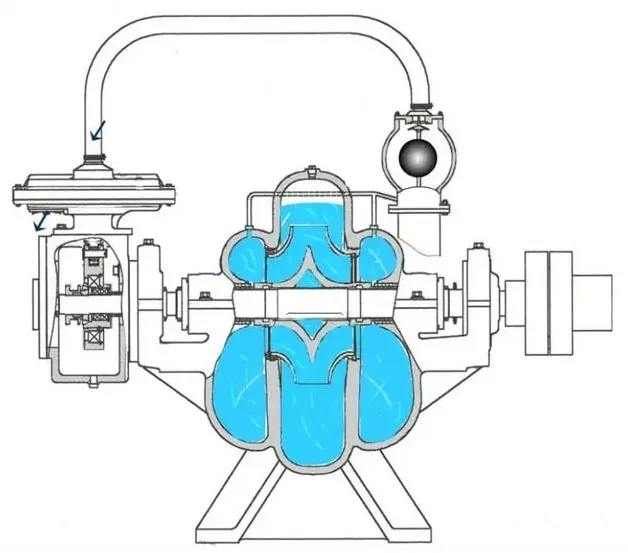

A double suction water pump is a centrifugal pump with two suction ports. Unlike traditional single-suction pumps, double-suction pumps can suck liquid from two suction ports at the same time. It generates centrifugal force through the rotation of the rotor, draws the liquid into the pump body, and discharges it through the outlet. This design enables the double suction water pump to have a high flow capacity and can reduce the influence of axial force.

The basic components of a double-suction pump include a high-speed rotating impeller and a fixed snail-shaped pump casing. The impeller usually consists of 4 to 12 backward curved blades, which are fastened to the pump shaft and driven by a motor to rotate at high speed. The impeller is a component that directly transmits power to the liquid in the pump, and is the energy conversion device of the pump. The pump casing has a suction port, which is connected with a suction pipeline, and a one-way bottom valve is installed at the bottom of the suction pipeline. There is a discharge port on the side of the pump casing, which is connected to the discharge pipeline installed with a regulating valve.

at high speed. The impeller is a component that directly transmits power to the liquid in the pump, and is the energy conversion device of the pump. The pump casing has a suction port, which is connected with a suction pipeline, and a one-way bottom valve is installed at the bottom of the suction pipeline. There is a discharge port on the side of the pump casing, which is connected to the discharge pipeline installed with a regulating valve.

After starting the double-suction pump, the pump shaft drives the impeller to rotate at a high speed, so that the liquid pre-filled between the blades starts to rotate. Under the action of inertial centrifugal force, the liquid moves radially from the inside of the impeller to the outside. The liquid gains energy when passing through the impeller, the static pressure energy increases, and the flow velocity increases. When the liquid leaves the impeller and enters the pump casing, the flow path gradually expands, the liquid gradually decelerates, and part of the kinetic energy is converted into static pressure energy, which flows into the discharge pipe along the tangential direction. Therefore, the volute pump casing is not only a part that collects the liquid flowing out of the impeller, but also an energy conversion device. When the liquid is thrown out of the impeller, a low-pressure zone is formed inside the impeller, and the liquid is sucked into the impeller by the difference between the liquid level of the storage tank and the total potential energy of the impeller. The impeller rotates continuously, so that the liquid is continuously sucked in and discharged. The mechanical energy gained by the liquid in the pump is expressed as increased static pressure energy.

double suction water pumps are widely used, mainly including industry, construction, agriculture, urban water supply and drainage, and water conservancy projects. In the industrial field, they are used for water supply, circulating water, cooling water, process flow and raw material transportation, etc. In the field of construction, double suction water pumps are used in building water supply, air conditioning systems and water supply and drainage systems. In agriculture, they are used in irrigation, irrigation and drainage systems and in the processing of agricultural products. In the field of urban water supply and drainage, double suction water pumps are widely used in water supply plants, sewage treatment plants and pumping stations. In hydraulic engineering, they are used in dams, hydropower plants and irrigation systems. In general, the double-suction pump is a multi-functional liquid delivery equipment that can meet the needs of large-flow liquid treatment and play an important role in various fields.

Features:

High flow capacity: The double suction water pump adopts a double suction port design, which can suck liquid from two suction ports at the same time, providing greater flow handling capacity. Compared with single-suction pumps, double-suction pumps can handle more liquid at the same speed.

handle more liquid at the same speed.

Reduced axial force: Due to the double-suction design of the double-suction water pump, the liquid enters the pump body from two directions, and the generated axial forces cancel each other out. This design effectively reduces the load on bearings and mechanical seals, improving the reliability and service life of the pump.

Balanced operation: The impellers of double-suction pumps are usually of a symmetrical structure, allowing the pump to maintain balance during operation. This balanced design helps reduce vibration and noise, and improves operational stability and safety.

Various sizes and models are available: double suction water pumps of various sizes and models are available on the market to meet the needs of different flow rates and lifts. Users can choose the appropriate double suction water pump according to the specific application requirements.

Wide application fields: double suction water pumps are suitable for many fields, including industry, construction, agriculture and water conservancy projects, etc. They are widely used in liquid handling tasks such as water supply, circulating water, cooling water, drainage and irrigation.

Advantage:

Its high flow capacity enables it to draw liquid from two suction ports simultaneously, providing greater flow handling capacity. By reducing the axial force, the double suction water pump reduces the load on the bearings and mechanical seal, thus improving the reliability and service life of the pump. It adopts the impeller of symmetrical structure to maintain balanced operation, reduces vibration and noise, and improves the stability and safety of the pump. At the same time, the double-suction pump realizes high-efficiency liquid transportation and treatment through optimized flow channel shape and impeller geometric parameters, and meets various needs. These advantages make double suction water pumps widely used in fields such as industry, construction, agriculture and water conservancy engineering, providing reliable and efficient solutions for liquid handling tasks.

Classification according to structure type:

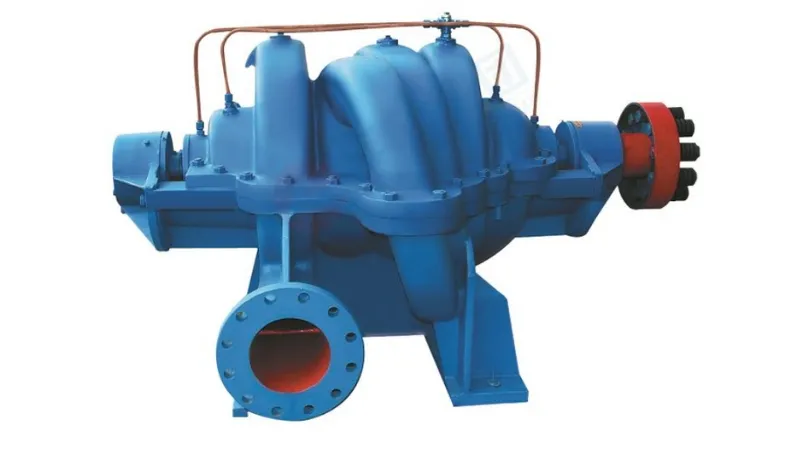

Horizontal double-suction pump: The inlet and outlet of the horizontal double-suction pump are on the same level, which is suitable for horizontally arranged systems.

Vertical double-suction pump: The inlet and outlet of the vertical double-suction pump are vertically arranged, which is suitable for occasions where space is limited or vertical installation is required.

Classification according to impeller arrangement:

Backward Curved Impeller double suction water pump: The blades of the impeller are curved behind the fluid inlet and outlet, suitable for applications handling high flow and low head.

Forward curved impeller double suction water pump: The blades of the impeller are curved in front of the fluid inlet and outlet, suitable for handling low flow and high head applications.

Classification according to axis position:

Horizontal double suction water pump: the pump shaft is in a horizontal position, suitable for horizontally arranged systems.

Vertical double suction water pump: the pump shaft is vertically arranged, suitable for systems with vertical arrangement or limited space.

Classified according to working style:

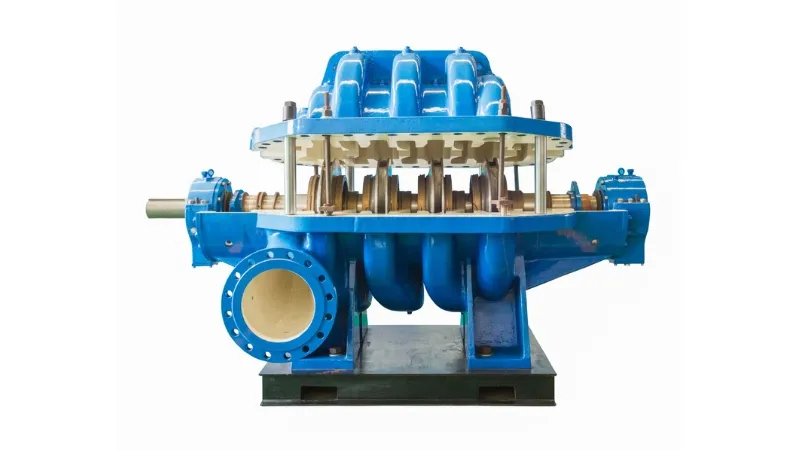

Single-stage double-suction pumps: Single-stage double-suction pumps have a single impeller for low head and high flow applications.

Multi-Stage double suction water pumps: Multi-stage double-suction pumps have multiple impellers for high head and high flow applications.

There are differences between single-suction pumps and double-suction pumps in terms of the number of suction ports, axial force balance, structure type, and application range. Single-suction pumps have only one suction port, are relatively small in construction, and are suitable for general liquid transfer and handling tasks. The double suction water pump has two suction ports, which can provide greater flow handling capacity, and the axial force is balanced, which is suitable for application scenarios that need to handle large flow liquids. The selection of the appropriate pump type should be determined according to the specific liquid handling needs and application scenarios.

There are several factors to consider when choosing a double suction water pump:

Flow requirements: First of all, it is necessary to determine the liquid flow to be processed. According to actual needs, choose a double-suction pump that can meet the flow requirements to ensure that it can handle the required liquid flow.

Head requirements: Determine the head height of the liquid, that is, the height that the liquid needs to be lifted. Select a suitable double-suction pump according to head requirements to ensure sufficient head capacity.

Working environment: Consider the working environment characteristics of the double suction water pump, including liquid temperature, viscosity, solid particle content, etc. Choose a double-suction pump that is resistant to high temperature, corrosion, and adapted to specific working conditions.

Pump efficiency: Consider the efficiency of the pump and choose a double-suction pump with higher efficiency to reduce energy consumption and operating costs.

Reliability and durability: choose a double-suction pump with high brand awareness, reliable quality, and good reputation. Check the material, design and manufacturing quality of the pump to ensure the pump has a long service life and stable operation.

Maintenance and service: Consider the after-sales service and maintenance support provided by the supplier. Choose a supplier with a professional maintenance team and reliable after-sales service to ensure the normal operation and maintenance of the double suction water pump.

Cost-effectiveness: Considering factors such as price, performance, quality and service life, choose a cost-effective double-suction pump to ensure satisfactory performance and reliability.

In order to prolong the life of the pump, you can do the following points after normal use:

Regular inspection: Regularly check the operating status and performance of the double-suction pump, including pump noise, vibration, temperature, etc. Watch for abnormalities or leaks.

Clean the pump body: Regularly clean the external surface of the double suction water pump and the inside of the pump body to ensure good ventilation and heat dissipation of the pump. Clear debris and blockages around the pump to keep it unobstructed.

Lubricating parts: According to the requirements of the pump, regularly check and replace the lubricating oil or grease to ensure the normal operation and lubricating effect of the lubricating parts.

Check the seals: Regularly check the seals of the double suction water pump, such as mechanical seals, packing seals, etc. Ensure the integrity of the seal and prevent leakage.

Clean the filter screen: If the double-suction pump is equipped with a filter screen or filter, clean and replace the filter screen regularly to prevent debris from entering the pump and affecting the normal operation of the pump.

Calibration and adjustment: Regularly calibrate and adjust the working parameters of the double-suction pump, such as head, flow, etc. Make sure the pump is always performing as required.

Pay attention to the temperature of the pump: monitor the temperature of the double suction water pump to ensure that the operating temperature of the pump is within the normal range. Excessive temperatures can cause malfunction and damage to the pump.

Regular maintenance: Regular maintenance, such as cleaning, tightening bolts, lubrication, etc. Carry out necessary maintenance and maintenance work according to usage conditions and manufacturer's recommendations

The following points can be considered:

Brand reputation: Choose a double suction water pump manufacturer with a good brand reputation and word of mouth. Learn about its reputation, history and market position in the industry, as well as customer reviews and feedback.

Technical Strength: Consider the manufacturer's technical strength and R&D capabilities. Learn about its professional knowledge and experience in the field of double-suction pumps, and whether it has advanced production equipment and processes.

Quality Control: Pay attention to the manufacturer's quality control system and certification status. Ensure that it has an effective quality management system, such as ISO 9001 certification, and can provide products that comply with relevant standards and specifications.

Customer service and support: Choose a manufacturer that offers comprehensive customer service and support. Learn about its pre-sales consultation, after-sales service, maintenance support and spare parts availability. Pay attention to whether the manufacturer can respond to customer needs and solve problems in a timely manner.

Experience and reference cases: Consider the experience and success stories of manufacturers in similar projects and application areas. Find out if it has provided successful solutions in related industries or projects.

Price and cost performance: comprehensively consider the price and cost performance of double suction water pump manufacturers. Not only focus on price, but also evaluate product quality, performance, reliability and after-sales support to get the best price/performance ratio.

Market Support and Distribution Network: Consider the manufacturer's market support and distribution network. Find out about its coverage in local and international markets, and whether it has a professional distribution channel and after-sales service network.

Market development trend :

Technological innovation and intelligence: With the continuous advancement of science and technology, double-suction pumps are developing in a more efficient and intelligent direction. The application of new materials, designs and control technologies enables double suction water pumps to provide better performance, higher energy efficiency and smarter operation.

double suction water pumps to provide better performance, higher energy efficiency and smarter operation.

Energy efficiency and sustainable development: Energy saving and environmental protection have become important issues of global concern, and the double suction water pump market has also been affected. More and more industries and applications require higher energy efficiency and sustainability, so double suction water pump manufacturers are committed to developing more energy-efficient and low-energy products to meet market demands.

Automation and remote monitoring: With the advancement of industrial automation and digitalization, the automation and remote monitoring functions of double suction water pumps have been enhanced. Through sensors, data acquisition and remote monitoring systems, operators can monitor and control the operating status of double-suction pumps in real time, improving operation and maintenance efficiency and fault diagnosis capabilities.

challenge :

Intense competition in the market: The double suction water pump market is highly competitive and there are many manufacturers and brands. Manufacturers need to continuously innovate and improve product performance to maintain a competitive advantage and meet customer demands.

Cost pressure: Cost is one of the ongoing challenges facing manufacturers. Factors such as fluctuations in raw material prices and increased labor costs may have an impact on the production cost of double suction water pumps, and manufacturers need to find ways to reduce costs while maintaining product quality and performance.

Technical difficulties and innovation needs: In order to meet the growing market demand, double suction water pump manufacturers need to constantly face technical difficulties and carry out innovation and research and development. Technical challenges in coping with complex working conditions, improving efficiency, and reducing noise and vibration are problems that manufacturers need to solve.

Environmental regulations and standards: Increasing environmental regulations and standards place higher demands on the design and manufacture of double suction water pumps. Manufacturers need to ensure that products comply with relevant regulations and standards, while meeting requirements for environmental protection and sustainable development.

Double suction water pump is an efficient and reliable pump equipment, which plays a vital role in the industrial field. By making full use of the characteristics and advantages of double-suction pumps, we can achieve more stable and efficient fluid delivery and processing, improve work efficiency, reduce energy consumption, and bring more convenience and benefits to all walks of life. If you have any questions, please contact us!

.png)