Fourth section Variable-diameter operation of vane pump

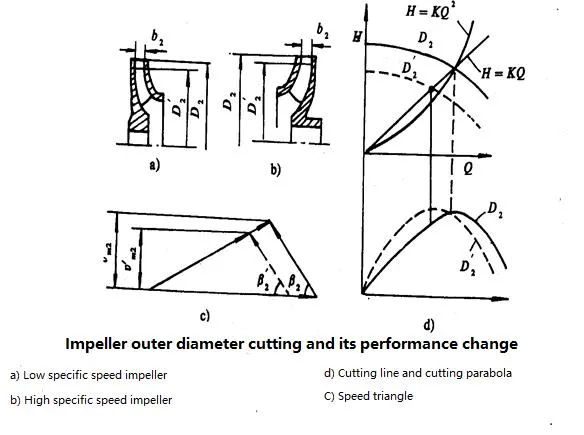

Variable-diameter operation means cutting off part of the original impeller of vane pump on lathe along the outer diameter. After the impeller is cut, the performance of the pump will change according to certain rules, thus changing the working point of the pump .

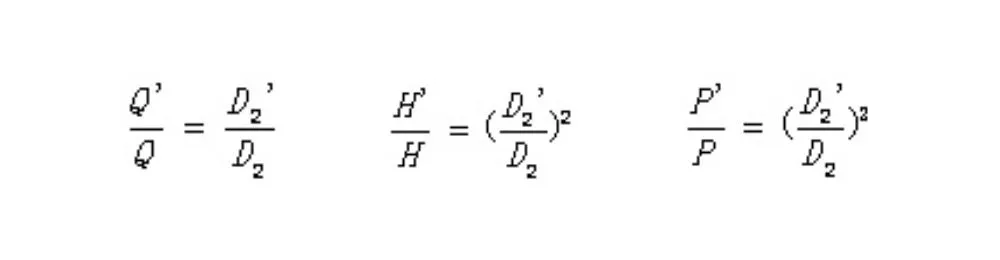

Cutting law

Within a certain range of cutting amount, the efficiency of water pump before and after cutting can be regarded as unchanged .

Problems needing attention in cutting impeller

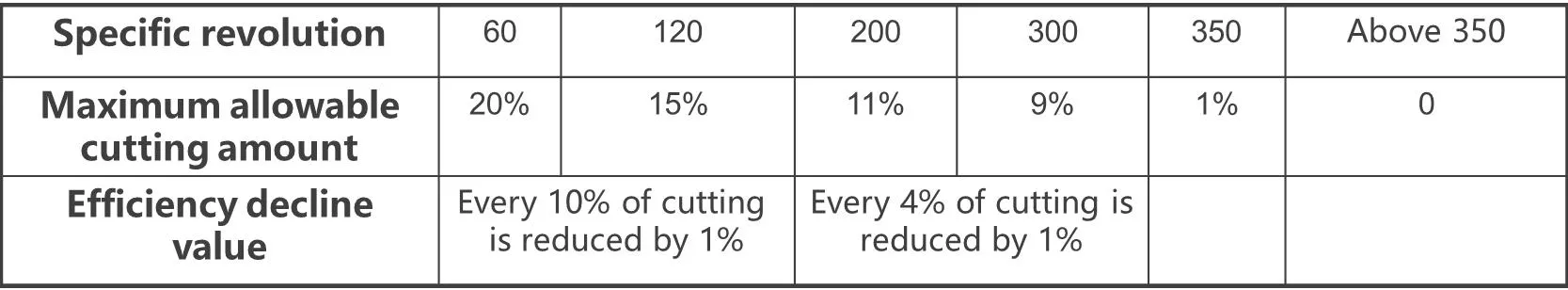

There is a certain limit to the cutting amount of the impeller, otherwise the structure of the impeller will be destroyed, and the water outlet end of the blade will become thicker, and the clearance between the impeller and the pump casing will increase, which will cause the efficiency of the pump to drop too much. The maximum cutting amount of impeller is related to the specific speed.

Cutting the impeller of water pump is a method to solve the contradiction between the limitation of pump type and specification and the diversity of water supply objects, which expands the application range of water pump. The working range of the pump is usually the curve section where the maximum efficiency of the pump decreases by no more than 5%~8% 。

Example:

Model:SLW50-200B

Impeller outer diameter: 165 mm, head: 36m.

If we turn the outside diameter of the impeller to: 155 mm

H155/H165= (155/165)2 = 0.852 = 0.88

H(155) = 36x 0.88m = 31.68m

To sum up, when the impeller diameter of this type of pump is cut to 155mm, the head can reach 31 m.

Notes:

In practice, when the number of blades is small, the changed head is larger than the calculated one.

.png)