Cavitation of Pump: Theory and Calculation

Overview of cavitation phenomenon

The pressure of liquid vaporization is the vaporization pressure of liquid (saturated vapor pressure). The vaporization pressure of liquid is related to temperature. The higher the temperature, the greater the vaporization pressure. The vaporization pressure of clean water at room temperature of 20℃ is 233.8Pa. While the vaporization pressure of water at 100℃ is 101296Pa. Therefore, clean water at room temperature (20℃) begins to vaporize when the pressure drops to 233.8Pa.

When the pressure of liquid is reduced to the vaporization pressure at a certain temperature, the liquid will produce bubbles, which is called cavitation. However, the vapor in the bubble is actually not completely steam, but also contains gas (mainly air) in the form of dissolution or nucleus.

When bubbles generated during cavitation flow to high pressure, their volume decreases and even bursts. This phenomenon that bubbles disappear in liquid due to pressure rise is called cavitation collapse.

The phenomenon of cavitation in the pump

When the pump is in operation, if the local area of its overflow part (usually somewhere behind the inlet of the impeller blade). For some reason, when the absolute pressure of the pumped liquid drops to the vaporization pressure at the current temperature, the liquid begins to vaporize there, generating steam and forming bubbles. These bubbles flow forward with the liquid, and when they reach a certain high pressure, the high pressure liquid around the bubbles forces the bubbles to shrink sharply and even burst. When the bubble bursts, liquid particles will fill the cavity at high speed and collide with each other to form water hammer. This phenomenon will cause corrosion damage to the over-current components when it occurs on the solid wall.

This process is the pump cavitation process.

Influence of pump cavitation

Produce noise and vibration

Corrosion damage of over-current components

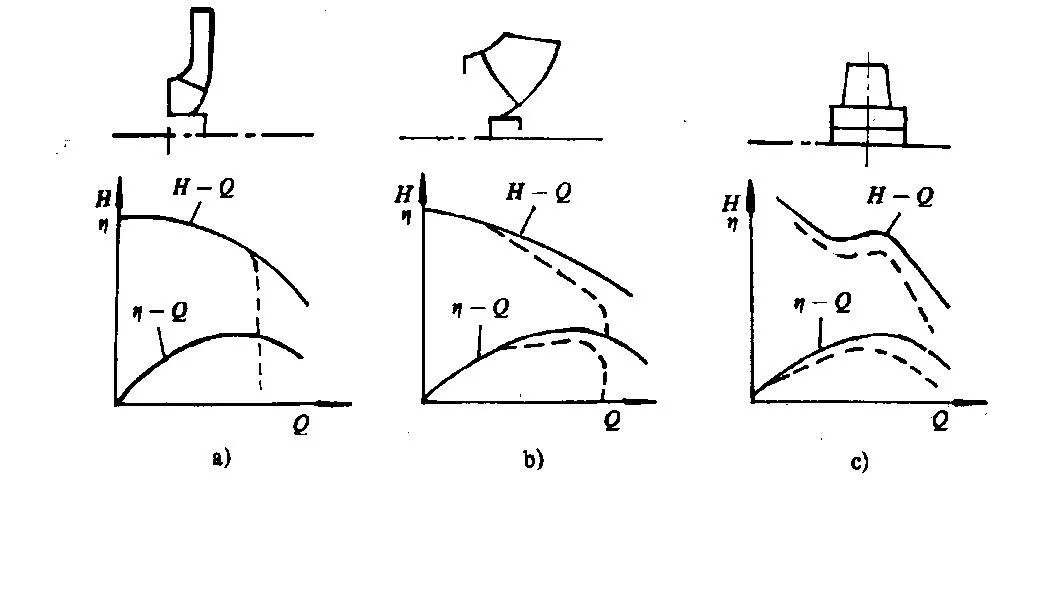

Performance degradation

Pump cavitation basic equation

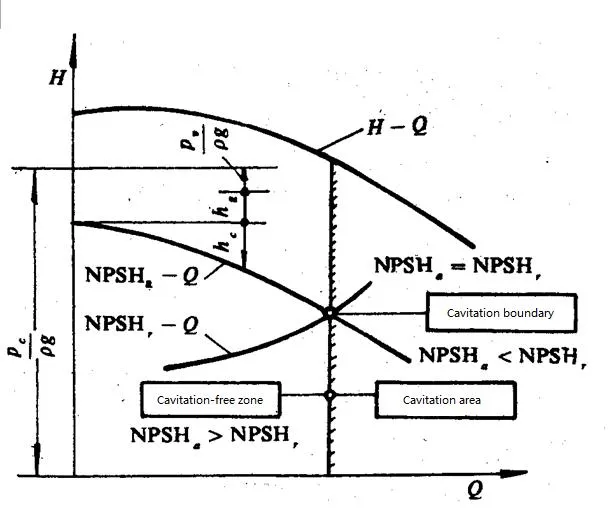

NPSHr-Pump cavitation allowance is also called necessary cavitation allowance, and it is called necessary net positive head abroad.

NPSHa-The cavitation allowance of the device is also called effective cavitation allowance, which is provided by the suction device. The greater the NPSHA, the less likely the pump will cavitation. NPSHa decreases with the increase of traffic.

Relationship between NPSHa and NPSHr when flow changes

Calculation method of device cavitation

hg=Pc/ρg-hc-Pv/ρg-[NPSH]

[NPSH]-Allowable cavitation allowance

[NPSH] = (1.1 ~ 1.5) NPSHr

When the flow rate is large, take a large value, and when the flow rate is small, take a small value.

.png)